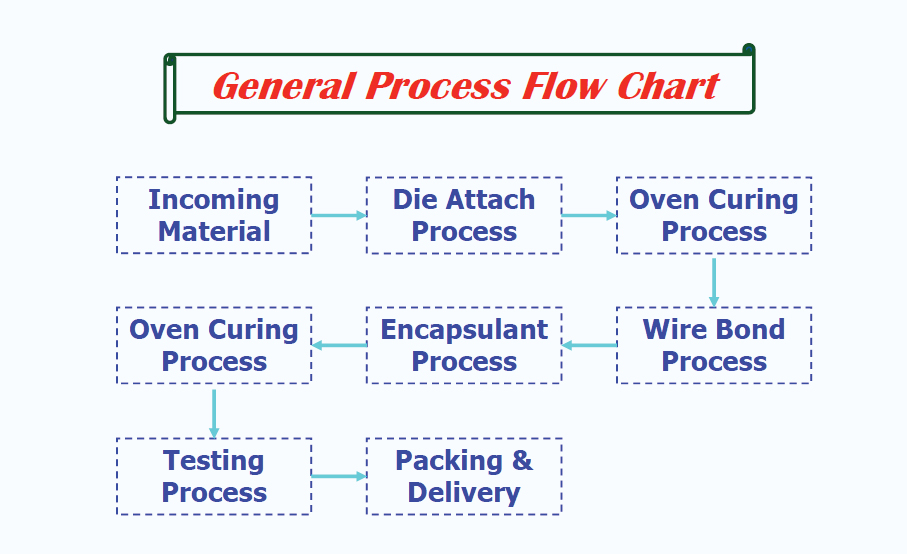

Process Quality Control

- Incoming Material

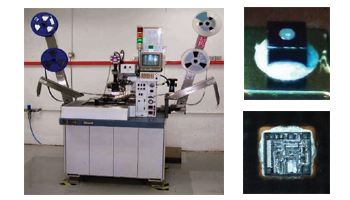

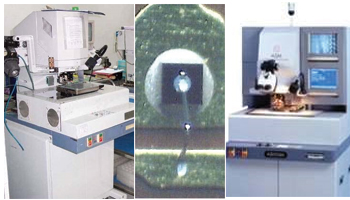

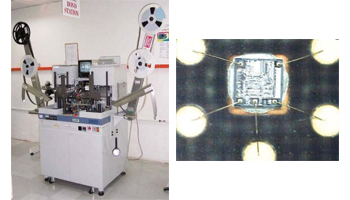

- Qty, Inspection Part no. - Die Attach

- Die Shear Test, Epoxy Coverage, QC Sampling AQL105G Normal II. - Oven Curing - Temperature.

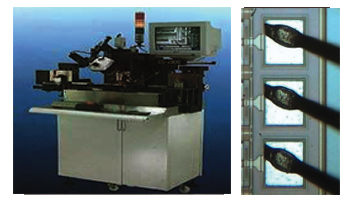

- WB - Bonding Accuracy, Wire Pull Test.

- Encap - Bubbles, Height.

- Final - Functional Test.

- QA Buyoff

- Packing